Seamless Gutter Machine Maintenance: What You Should Know

Updated for 2025

Maintaining your seamless gutter machine helps ensure its longevity—years or even decades. Regular maintenance will keep your machine reliable and deliver quality seamless gutters to your customers.

Imagine you never changed the oil, flushed the brake fluid, replaced worn belts, or did any kind of routine maintenance on your truck? How long do you think it would hold up? And how much would it cost to repair the resulting damage?

It might be a no-brainer, but simply checking over your machine regularly and inspecting the parts can help you avoid big repair and service costs.

At New Tech Machinery (NTM), our Service Department experts are a phone call away, ready to assist with any service-related issues. However, you can avoid many problems through regular maintenance.

In this article, we’ll dig into:

- Why keeping up with routine maintenance on your seamless gutter machine is important

- How often you should perform maintenance on your portable gutter machine

- What kind of maintenance you should be doing on your gutter machine

Why Is Seamless Gutter Machine Maintenance Important?

Buying a portable gutter machine is a long-term investment. .

If you want to make sure you get the most out of your machine, deliver high-quality products to your customers, and avoid racking up even bigger service costs in the future, keeping your gutter machine well maintained should be a priority.

Some benefits of taking care of your gutter machine properly and regularly include:

- Keeping your machine running for a long time

- Improving the quality of the gutters produced

- Saving you time and money on future repairs, parts, and service

- Allowing for safer and better performance from your machine

- Increasing the life of your machine and its components

Portable seamless gutter machines can produce different styles of gutters more quickly than in-plant rollformers. However, they can also encounter problems just as fast if not taken care of with a routine maintenance procedure.

Without regular machine maintenance, you risk:

- Losing work and money due to needing service or repairs on your machine

- Delaying run times

- Fabricating flawed gutters, slowing down the installation process and costing you more time and money

- Low customer satisfaction as a result of machine problems, and inferior-quality products

Problems with Dirt, Debris, and Foreign Objects

Rollers can become damaged if debris and dust collect on them, or if objects are left inside the machine. That’s why it’s important to do thorough inspections to make sure your gutter machine is clean, inside and out. Otherwise, you can spend a lot of time and money on replacement parts.

It’s also important that your seamless gutter machine remains empty of material when not in use, or when transporting the machine to and from jobs. This helps prevent dust and dirt from collecting inside the machine.

Also, foreign materials inside your gutter machine could cause indentations on your gutter. Rippling or indentation ripple on the bottom of the gutter is not an inherent condition of NTM gutter machines.

An indentation in the gutter, on the face or bottom, that repeats itself can easily be detected. This may be indicative of foreign material (tape, caulking, etc.) that’s stuck to a top or bottom roller gouging a roller.

Determine if the dent is from the inside out, or outside in. If the dent is from the inside, there’s something stuck or damaged on a top drive roller, face inside roller, inside box roller, or skate bearing.

An indentation from the outside means there’s something stuck or damaged on a bottom drive roller, bottom keel roller, outside face roller, or outside box roller. To correct it, locate the foreign material, or burr, and clean, file, or remove with emery cloth as required to smooth out the roller.

Problems with Improper Lubrication

Improper lubrication can cause problems with your gutter machine’s shear blade and dies, chains, and entry guide carriage. Inadequate lubrication of the shear may cause rust to form, premature failure of the blade and dies, and you won’t have a clean cut on the finished gutters.

Should the lube get on the drive or forming rollers, that can also cause issues. Drive rollers will slip on the material, preventing adequate movement, and the forming rollers will leave oil marks on the gutters. Debris, lube, and foreign objects on the drive rollers can cause damage or marring of paint on the material.

What’s Involved in Seamless Gutter Machine Maintenance?

Similar to roof panel machine maintenance, there are some best practices to keep in mind that will help preserve the life and functions of your seamless gutter machine, and the quality of your work. If you’re using your portable gutter machine every day, practicing good habits of inspecting your machine weekly and keeping it cleaned can help ensure a long-lasting machine.

Common best practices to keeping your gutter machine in prime condition include:

- Making any necessary machine adjustments

- Keeping the machine clean and free of debris and dust. This helps ensure that the rollers won’t be affected by dirt, and that material won’t get damaged. This allows for better performance by your machine.

- Avoiding storing the machine outdoors for long periods. Cover it with a tarp but make sure there’s enough ventilation to prevent condensation and rust.

- Avoiding storing, and/or transporting the machine with metal material in the rollers or fed into the machine. Material left inside the machine acts as a bowl, catching dirt and debris, and could end up harming the rollers and end-product.

- Inspecting that all parts work the way they should and that nothing is damaged. Also, check for overwear on screws and bolts, as well as the turning of the free-moving rollers and bearings, to ensure smooth and proper operation.

- Checking for any fluid or oil leaks, either from hydraulic systems or if your machine is powered by gas (like the BG7™ Box Gutter Machine).

- Inspecting fuses, batteries (if you have a gasoline engine), electrical connections, and controllers to make sure there are no shortages or wiring problems.

- Checking chain tension. Chains on the seamless gutter machine should be just snug, not over-tightened or too loose. Over time the chains will wear down, so keeping them tightened is key to keeping everything working smoothly. Chains should have no tighter than 1/2” of play.

How Often Should Seamless Gutter Machine Maintenance Be Done?

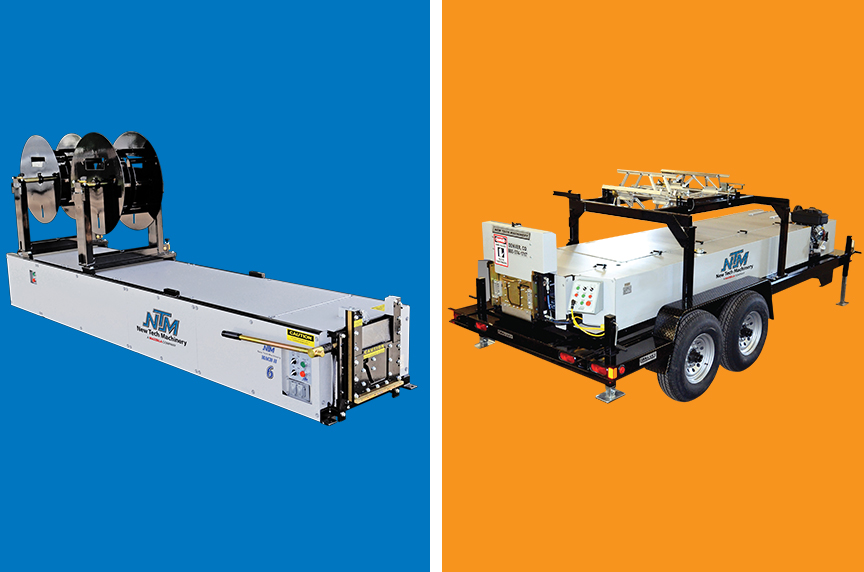

The more you use your machine, the more often it will need maintenance. However, there are some recommended actions you can take regularly to keep your seamless gutter machine in top shape. Please note that not every gutter machine follows these recommendations, so refer to your specific machine manual for the exact timing. Here are some examples of maintenance recommendations based on operation time and routines for our MACH II™ Gutter Machines and BG7™ Gutter Machines, depending on which one you have:

Every 30 hours of operation – On the BG7 machine, you’ll want to lubricate the drive gears during this time with an Open Gear Spray Lubricant.

Every 40 hours of operation – On both types of machines, lubricate the chains on both gutter machines using a dry motorcycle lube or equivalent.

Every 30 cuts – On both the MACH II and BG7 machines, lubricate both faces of the gutter machine’s Shear Blades and Dies a minimum of every 30 cuts with Spray Lube, or whenever cutting surfaces begin to look dry.

Daily – On the BG7 machine, you should also clean the Shear Assembly Top Blades, Bottom Dies, and Male/Female dies at least once a day, or whenever cutting surfaces look dry.

Weekly – On the Mach II machines, clean the Shear Assembly Blade and Dies at least once a week during normal use.

Since the BG7 Box Gutter Machine’s shear is hydraulically driven, you’ll also want to check the hydraulic fluid levels weekly. It should be approximately 5” below the top of the filler neck.

When checking the fluid level, also make sure that it’s clear in color. White milky-colored fluid signifies water contamination, and you should change the fluid. Dark fluid indicates a dirty oil filter, and you’ll want to replace the filter.

Yearly – Hydraulic fluid and filter in the BG7 machine should be changed each year. This oil will degrade if it remains stagnant for too long in the machine. Also, lubricate the main drive shaft bearings on the back side of the main drive plate.

Every year, you’ll also want to spray both the MACH II and BG7 machine’s Entry Guides with Spray Lube, then loosen the left and right guide and slide along the rods to disperse the lubricant evenly. Also, on the MACH II 5”/6” combo machine you can lube the slide shaft with a lite oil, and the adjusting screws.

Twice a year – Check chain tension and adjust as necessary on Mach II and BG7 machines.

On the BG7 machine’s expandable arbor nut, there is a grease zerk fitting in the collar of the threaded nut that should be lubricated at least twice a year, or whenever grease is not visible on the threads of the shaft.

Seamless Gutter Machine Maintenance: Tips and Guidelines

For these seamless gutter machine maintenance guidelines, we’re going to use the manual for the MACH II 5”, 6” and 5”/6” combo machines. General maintenance actions are similar for all of the NTM portable gutter machines. For specifics, we always advise you to refer to your machine manual which will provide you the best instructions to take to maintain your equipment.

Remember, before doing any maintenance on your gutter machine:

- Read and understand the machine manual before attempting to operate the machine.

- Always keep guards, covers, and lids mounted to the machine during operation.

- Observe and obey all safety and warning signs affixed to the machine.

- Always adhere to and follow all local and national safety codes concerning the loading and unloading of reeled coils.

- Use only properly rated devices for lifting reeled coils into or out of the reel stand assembly.

- Do not wear loose clothing, jewelry, etc. that could become entangled in moving parts of the machine when in operation.

- Stop the machine and disconnect power before attempting to make any adjustments, perform any maintenance or changeover procedures.

- Do not use solvents to clean drive rollers.

General maintenance items to perform on your MACH II machines are as follows:

- Always keep covers on during operation and storage. The covers are for operator safety, but they also protect the internal components of the machine from the environment.

- Avoid storing the machine outdoors for long periods of time. Cover the machine with a tarp or machine cover (optional) for protection, and make sure to provide good ventilation to prevent condensation and rust.

- Avoid storing or transporting the machine with metal material in the rollers or fed into the machine.

- Keep the machine clean. This increases the life of the machine and makes maintenance easier, as well as provides a clean product.

- Before operating the machine, visually inspect for foreign objects, debris, or anything unusual. If something doesn’t seem right, inspect and remedy before operation of the machine.

- Keep chains properly tensioned. This will add to the life of the chains and sprockets. The chains should be just snug. An over-tightened chain is just as bad for the machine as a loose chain.

- Lubricate the chains a minimum of every 40 hours of operation, or when dry. It is preferable to use a dry motorcycle chain lube or equivalent.

- Keep Entry Guide Carriage clean and lubricate as needed with Spray Lube.

- Keep Cradles lubricated with Clear Grease.

- Clean Forming Rollers as needed with a Scotch Brite Pad and a small amount of solvent.

- Clean Drive Rollers with soap and water or mild solvent-free spray cleaner as needed. Do not use harsh chemicals or solvents or damage will occur.

- Lubricate both faces of the shear blades and dies with spray lube at least once daily. Add more as needed before the cut edges begin to deteriorate.

(Note: The shear has a safety pin to prevent the shear handle from rotating when transporting the machine or removing the shear from the machine. The shear is a very dangerous apparatus. The safety pin must be in place when removing the shear from the machine. Failure to do so will allow the blade to protrude through the bottom of the shear and can cause severe injury.)

*Before performing any maintenance on your machine, please refer back to your specific machine manual, which can be found on our website. Specific instructions on how to perform maintenance actions, when to perform machine maintenance, and recommended lubricants to use can be found in each machine manual.

Final Thoughts

Seamless gutter machine maintenance doesn’t have to be a pain-staking process or take lots of time, as long as you keep up with a routine of cleaning and inspecting your machine and its parts. Not only will maintenance keep your machine running for a long time, but it can also:

- Keep your customers happy

- Save you future expenses on machine repairs or service

- Increase the life of the machine, and the quality of end-products

For over 30 years, New Tech Machinery has been manufacturing portable rollforming equipment and making sure our customers get the most out of their machines by providing them with best practices to use to keep their equipment running and in top condition.

If you ever have a maintenance question or need troubleshooting assistance refer to our Support page, please contact one of our expert rollforming service specialists today.